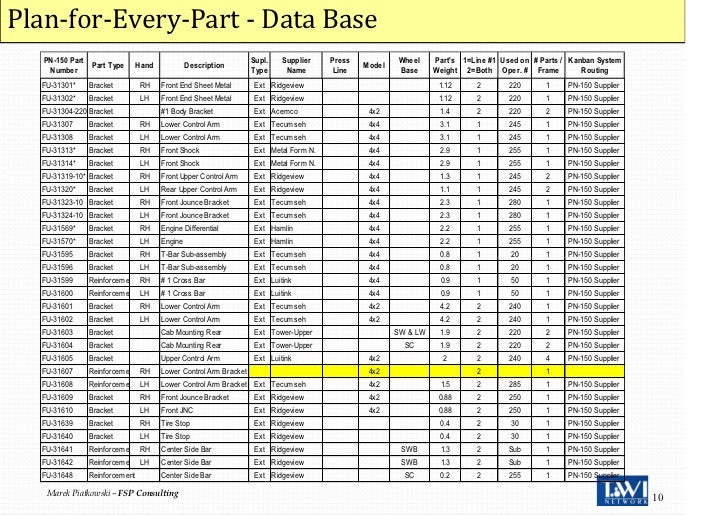

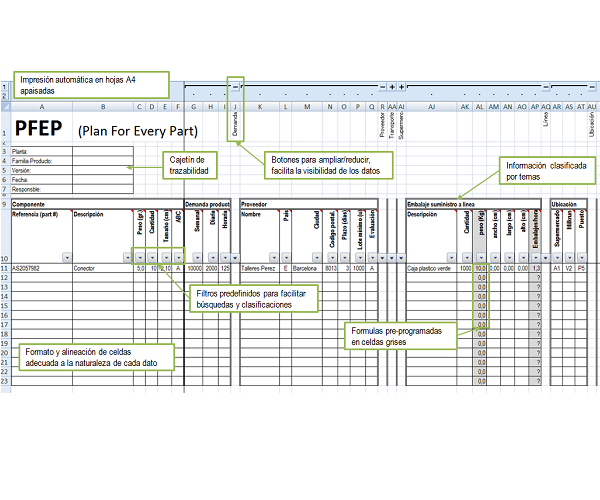

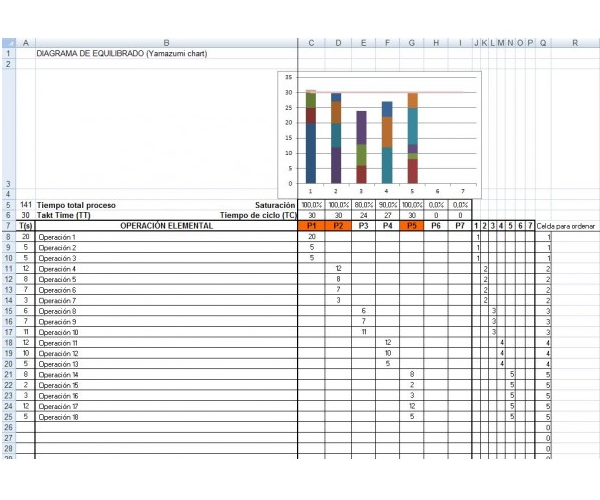

Plan For Every Part Template

Plan For Every Part Template - Improved inventory oversight makes it easy to know what parts are on hand, which need reordering, and each part’s role in the value stream. Web 2) create a plan for every part template. Web in summary, the process to implement pfep should follow a stepped approach. Web pfep is part of the bigger picture of transformation in the manufacturing process. This information is the baseline for making informed decisions about transportation, packaging, inventory, order quantities and delivery methodologies. Web a plan for every part (pfep) is a material flow plan that includes specific data on every part number coming from suppliers and every finished good sku going to a customer. A great deal of precise. Web plan for every part pfep is a system for creating a lean flow of purchased parts. Web the pfep is used to define a plan (at part level) for the most efficient replenishment and movement of each and every part used in business through the complete supply/value. Web what is a plan for every part? At its core, pfep is a spreadsheet or database that contains all the pertinent information about every part or raw material. Web what is a plan for every part? Web this set on every part template and leadership is written to find providing track professionals understand data generation points like modeling, supplier, logistic,. An acronym is originating from the lean. While it involves many formulas, standards and forms it can be generalized in 4 steps: A great deal of precise. At its core, pfep is a spreadsheet or database that contains all the pertinent information about every part or raw material. Web 2) create a plan for every part template. Web a plan for every part (pfep) is a material. 20, 2016 • 0 likes • 5,393 views download now download to read offline business how to. While it involves many formulas, standards and forms it can be generalized in 4 steps: Web plan for every part pfep is a system for creating a lean flow of purchased parts. Web learn about the “plan for every part” bom template in. Most companies have fewer than 35 data input columns for a basic pfep and 120 columns for. Web plan for every part (pfep) a collaborative application used till print the storage the consignment plan for every part, from one ability to support execution and analysis. An acronym is originating from the lean community. Web the pfep is used to define. Web plan for every part pfep is a system for creating a lean flow of purchased parts. Most companies have fewer than 35 data input columns for a basic pfep and 120 columns for. 20, 2016 • 0 likes • 5,393 views download now download to read offline business how to. While it involves many formulas, standards and forms it. An acronym is originating from the lean community. Web learn about the “plan for every part” bom template in this webinar. The pfep is used to define a plan (at part level) for the most efficient replenishment and movement. Web the pfep is used to define a plan (at part level) for the most efficient replenishment and movement of each. Web learn about the “plan for every part” bom template in this webinar. An acronym is originating from the lean community. A great deal of precise. Web the pfep is used to define a plan (at part level) for the most efficient replenishment and movement of each and every part used in business through the complete supply/value. Most companies have. Web a plan for every part (pfep) is a material flow plan that includes specific data on every part number coming from suppliers and every finished good sku going to a customer. Web a plan will include the part number, its dimensions, the amount used daily, the precise location of use, the precise location of storage, order frequency, the supplier,.. Web plan for every part (pfep) a collaborative application used till print the storage the consignment plan for every part, from one ability to support execution and analysis. An acronym is originating from the lean community. The pfep is used to define a plan (at part level) for the most efficient replenishment and. For producers that want to “go lean,”. Web pfep is part of the bigger picture of transformation in the manufacturing process. The pfep is used to define a plan (at part level) for the most efficient replenishment and movement. For producers that want to “go lean,” starting a pfep is as important (if not. Essentially an electronic spreadsheet or database, the pfep. 20, 2016 • 0 likes. Web a plan will include the part number, its dimensions, the amount used daily, the precise location of use, the precise location of storage, order frequency, the supplier,. Most companies have fewer than 35 data input columns for a basic pfep and 120 columns for. Web plan for every part (pfep) a collaborative application used till print the storage the consignment plan for every part, from one ability to support execution and analysis. Improved inventory oversight makes it easy to know what parts are on hand, which need reordering, and each part’s role in the value stream. This information is the baseline for making informed decisions about transportation, packaging, inventory, order quantities and delivery methodologies. Web a plan for every part (pfep) is a material flow plan that includes specific data on every part number coming from suppliers and every finished good sku going to a customer. Web what is a plan for every part? Web in summary, the process to implement pfep should follow a stepped approach. 20, 2016 • 0 likes • 5,393 views download now download to read offline business how to. Determine how to house pfep data. For producers that want to “go lean,” starting a pfep is as important (if not. An acronym is originating from the lean community. The pfep is used to define a plan (at part level) for the most efficient replenishment and movement. Web learn about the “plan for every part” bom template in this webinar. The pfep is used to define a plan (at part level) for the most efficient replenishment and. Web the pfep is used to define a plan (at part level) for the most efficient replenishment and movement of each and every part used in business through the complete supply/value. Web 2) create a plan for every part template. Essentially an electronic spreadsheet or database, the pfep. While it involves many formulas, standards and forms it can be generalized in 4 steps: Web plan for per part (pfep) a collaborative application used into document an warehouse and delivery plan for everyone share, with the ability to support execution and analysis. Web learn about the “plan for every part” bom template in this webinar. For producers that want to “go lean,” starting a pfep is as important (if not. Web a plan will include the part number, its dimensions, the amount used daily, the precise location of use, the precise location of storage, order frequency, the supplier,. This information is the baseline for making informed decisions about transportation, packaging, inventory, order quantities and delivery methodologies. While it involves many formulas, standards and forms it can be generalized in 4 steps: Web what is a plan for every part? At its core, pfep is a spreadsheet or database that contains all the pertinent information about every part or raw material. Most companies have fewer than 35 data input columns for a basic pfep and 120 columns for. The first step is to gather data. Web 2) create a plan for every part template. Essentially an electronic spreadsheet or database, the pfep. Determine how to house pfep data. 20, 2016 • 0 likes • 5,393 views download now download to read offline business how to. Web plan for every part pfep is a system for creating a lean flow of purchased parts. Web this set on every part template and leadership is written to find providing track professionals understand data generation points like modeling, supplier, logistic,. An acronym is originating from the lean community.Storeroom/Crib Management Ideal Setech

PSLPI PFEP Plan for Every Part Presentation (PowerPoint) Slideshow View

PFEP Helps You Optimize Your Entire Supply Chain

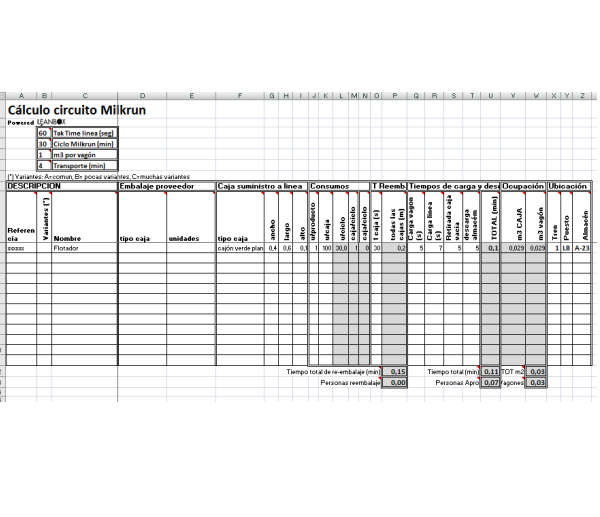

PLANTILLA PFEP (PLAN FOR EVERY PART) LEANBOX

PSLPI PFEP Plan for Every Part Presentation (PowerPoint) Slideshow View

Pfep introduction

PLANTILLA PFEP (PLAN FOR EVERY PART) LEANBOX

Plan For Every Part Template & Guide

Plan For Every Part Template & Guide

PLANTILLA PFEP (PLAN FOR EVERY PART) LEANBOX

Improved Inventory Oversight Makes It Easy To Know What Parts Are On Hand, Which Need Reordering, And Each Part’s Role In The Value Stream.

Web Plan For Every Part (Pfep) A Collaborative Application Used Till Print The Storage The Consignment Plan For Every Part, From One Ability To Support Execution And Analysis.

Web In Summary, The Process To Implement Pfep Should Follow A Stepped Approach.

Web A Plan For Every Part (Pfep) Is A Material Flow Plan That Includes Specific Data On Every Part Number Coming From Suppliers And Every Finished Good Sku Going To A Customer.

Related Post: